Didn't find the product you like?

We gonna help you find matched one fast

How Contouring Stick Factory Implements Quality Control?

2025-09-12

Daily routines built around basic cosmetics for women often include products designed to enhance natural features while remaining simple to apply. Among these, contouring sticks have become a key tool for shaping and defining facial structure. Behind their growing popularity lies the work of a contouring stick factory, where consistent quality control measures are applied to ensure that products meet both safety standards and consumer expectations. Understanding how these factories operate helps users and businesses alike make informed decisions about cosmetic products they use or source.

Sourcing Raw Materials with Care

Quality assurance starts with material selection.A contouring stick requires a blend of waxes, oils, pigments, and stabilizers. Factories typically assess suppliers based on ingredient purity and stability. Pigments undergo checks to confirm that they deliver consistent color without irritation. Similarly, oils and waxes are tested to ensure they provide the right texture for smooth application. By setting clear standards for sourcing, manufacturers reduce risks of inconsistencies that might affect performance or safety.

Maintaining Hygienic Production Environments

Clean manufacturing spaces are critical in cosmetics production. Contouring stick factories often implement controlled environments where air quality, humidity, and temperature are regulated. Workers are trained to follow hygiene protocols, wearing protective clothing to avoid contamination. Equipment is sanitized on strict schedules, and regular inspections verify that these processes are followed. These measures not only protect the integrity of the product but also ensure compliance with cosmetic safety regulations that apply in various markets.

Testing Formulas for Stability and Performance

Before a contouring stick reaches store shelves, its formula is subjected to multiple tests. Stability testing evaluates how the product reacts to temperature shifts, light exposure, and long-term storage. Performance testing focuses on application qualities, including texture, blendability, and adherence to skin. Products are also reviewed for color payoff, ensuring that shades remain consistent across batches. This stage helps factories confirm that the final product functions as intended in daily use.

Packaging as Part of Quality Control

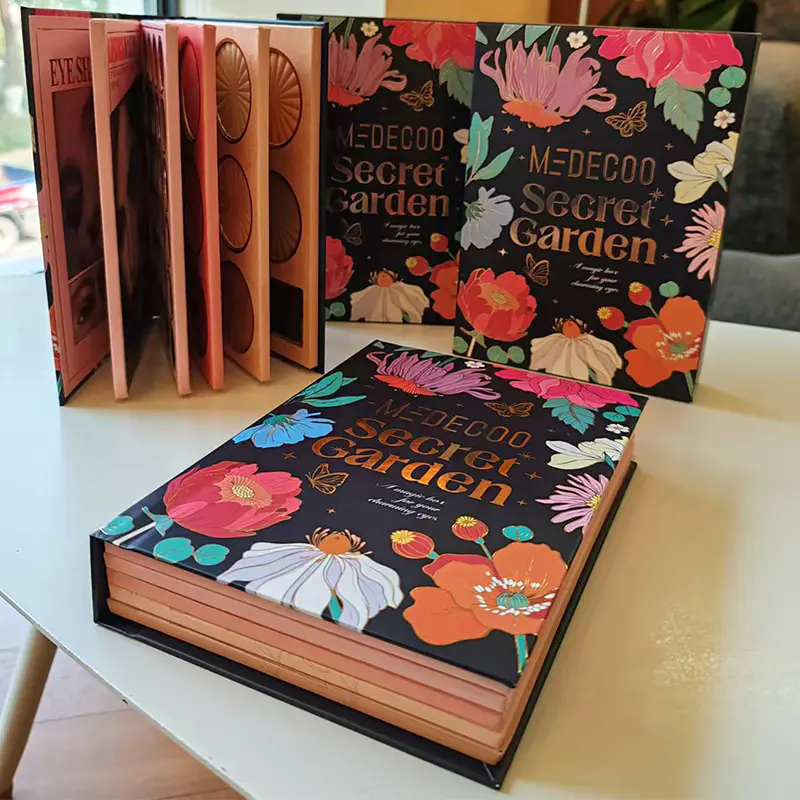

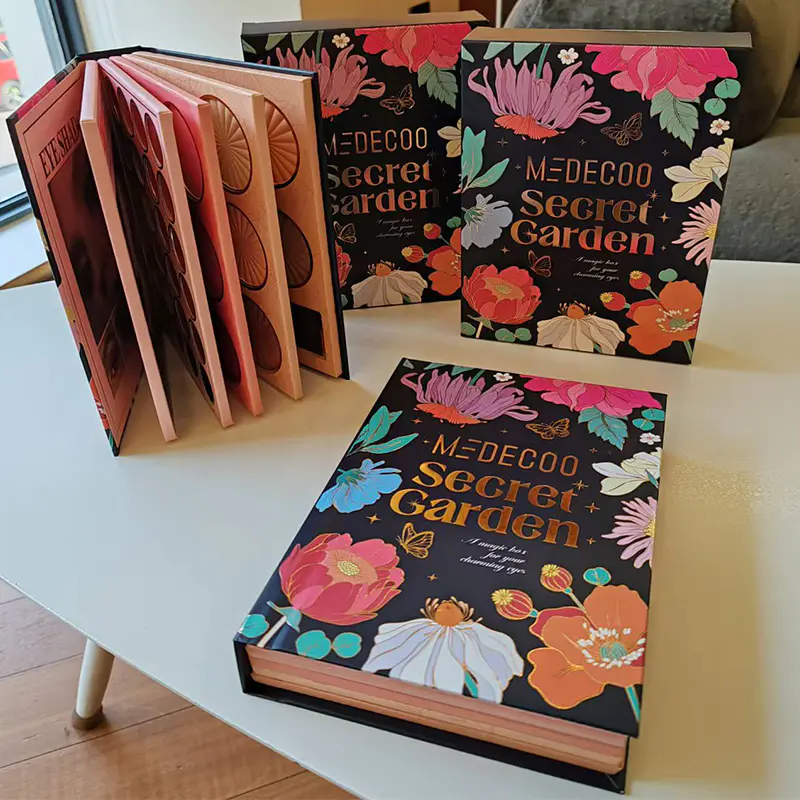

Quality does not end with the formula; packaging plays an equally important role. A contouring stick relies on its casing to maintain shape, prevent breakage, and provide ease of application. Factories conduct compatibility testing between formula and packaging to confirm that materials will not cause changes in texture or stability. Packaging is also evaluated for durability under transport and everyday handling, reducing the chance of damage before it reaches the end user.

Batch Sampling and Inspection Procedures

During mass production, factories often implement batch sampling. From every production cycle, random samples are pulled for detailed analysis. These tests may include microbial screening, visual checks, and measurements of consistency in color and texture. By identifying irregularities early, manufacturers can address potential issues before large quantities of product are distributed. This step provides an added layer of security for both businesses sourcing products and consumers applying them.

Certifications and Compliance Standards

Many contouring stick factories work toward recognized certifications, such as GMP (Good Manufacturing Practices) for cosmetics. Compliance demonstrates that processes are standardized and audited by external bodies. Factories may also align with regional safety regulations, such as FDA guidelines in the United States or EU cosmetic standards in Europe. For brands sourcing from these facilities, documented compliance provides assurance that products are aligned with international quality expectations.

Integrating Quality into Everyday Use

Understanding the quality control steps behind the scenes provides confidence in the safety and performance of these items. From material sourcing to packaging tests, each stage ensures that the contouring stick not only sculpts effectively but also withstands everyday handling. By paying attention to both visible and unseen details, factories contribute to routines that combine practicality with consistent results.

Language

Language

中文简体

中文简体 русский

русский Español

Español Deutsch

Deutsch عربى

عربى

0

0